3/18 Pages

In this episode, you’ll learn how Kawasaki has optimized their general purpose robots since they first hit the market in the mid 1980s, and an overview of the newest addition to the lineup: the RS013N…

Check out the RS013N spotlight in Packaging World to learn what makes our newest robot an industry leader for small-to-medium payload robots…

In the “new normal,” where virtual contact and social distancing are required, the number of workplaces where robots could play an active role is increasing…

Make no mistake about it. Kawasaki is robotics. But at the same time, we are not robots. Learn more…

In the industrial world, research and development of humanoid robots is accelerating. How far have humanoid robots come and where are they going? Let’s follow their footsteps…

UK machine builder Haith exclusively uses Kawasaki robots for their high performance and reliability. Learn about Haith’s form-fill-seal bagging system for aggregate, which features a Kawasaki CP180L palletizer…

Kawasaki’s remote COVID-19 testing prototype could help Japan streamline their testing measures while protecting medical workers. Learn more…

Kawasaki’s new autonomous underwater vehicle (AUV) is designed to efficiently maintain and inspect underwater pipelines located deeper than 400 meters – a dangerous task for human divers…

All of us at Kawasaki Robotics wish you and your loved ones health and happiness this holiday season, as well as a joyous start to the upcoming year.

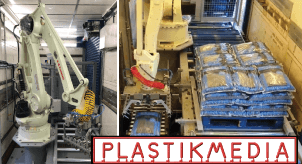

“Learn how this solution from Kawasaki and Gudel eliminated an extremely dangerous task from employees’ workload, creating a safer and more efficient work environment…

(PDF:300.6K

)”