By Norman Dixon, Controls Engineer at Kawasaki Robotics

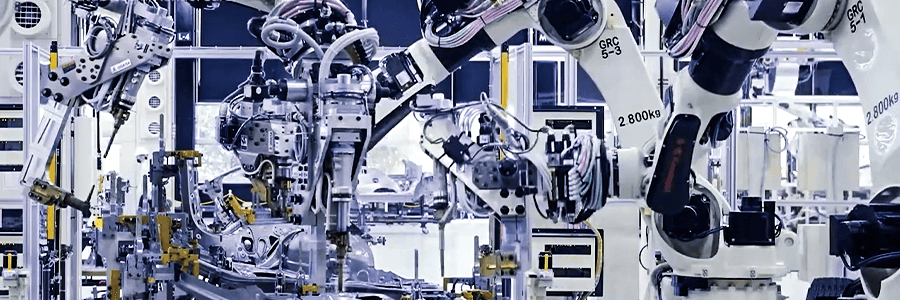

I work in the automotive division at Kawasaki Robotics, and I’ve worked directly with a whole lot of products in our lineup. All of them are trustworthy and capable, so it was hard to narrow it down to just five.

But we got there. Here are a handful of our notable difference-making robots, spanning applications from automotive to far beyond.

1. BX200: The All-Rounder

KEY SPECS

- Payload: 200 kg (440 lbs)

- Max reach: 2597 mm (102”)

- Mounting: Floor

APPLICATIONS

- Spot Welding

- Material Handling

- Machine Tending

I’d call the BX our workhorse. Its hollow wrist is perfect for housing cables and hoses, and the strong and lightweight arm makes it ideal for spot welding. So spot welding is a key BX application, but really, it’s tough to pin down just one because of how versatile it is.

I’ve seen the BX used in material handling (the payload capacity is a good size for automotive), machine tending and dispensing, applying sealants and inspection. You can mount a camera on the BX, and it can go to a specific location and compare the data it sees with your model. Excellent for error-proofing.

2. MG15: The Power Lifter

KEY SPECS

- Payload: 1500 kg (3,300 lbs)

- Max reach: 4005 mm (157”)

- Mounting: Floor

Lovingly referred to as Mega Godzilla around these parts, the MG has a surprisingly small footprint despite its impressive size. It uses a ball screw and nitrogen gas cylinder counterbalance design, and special kinematics with 11 swivel points for robot motion and weight distribution, plus 9 motors. Put simply, this 6-axis robot lifts 3,000+ pounds the same way you and I lift our computer mouse, and it does it with 0.05 mm repeatability.

You could give it some spot welding, but it’s not really designed to do that work. The key application for the MG is, without a doubt, material handling. This guy is heavy-duty. We originally designed it for aerospace, but we quickly got a whole lot of requests because of its payload. Customers get not only the ability to lift serious weight; they also get a robot that’s more accurate than they may ever need. The ball screw design makes it very rigid and repeatable.

3. CP 700: The Stack Master

KEY SPECS

- Payload: 700 kg (1,540 lbs)

- Max reach: 3255 mm (128”)

- Mounting: Floor

Being in automotive, this is the one robot on today’s list that I haven’t used. But I’ve heard and I know plenty about it, because it’s a top performer in palletizing.

If you need packaging and stacking, you’ll love the CP. Good payload with impressive speed and very easy-to-use palletizing software.

4. BA013N: The Welder

KEY SPECS

- Payload: 13 kg (29lbs)

- Max reach: 1492 mm (59”)

- Mounting: Floor

As you can tell from the specs, this is a compact and precise robot. Its key application is arc welding, so the heaviest thing on it is sure to be an arc welding torch.

I’ve worked with a lot of welders in my day—and also with a good amount of competing robots thanks to my history as an integrator—and it’s clear that the BA shines because of its feature set. This is probably the most user-friendly and feature-rich option in its category.

5. BU015X: The Seal of Approval

KEY SPECS

- Payload: 15 kg (33 lbs)

- Max reach: 2887.5 mm (113”)

- Mounting: Floor

A sealing robot that sports a 7th axis. Especially useful for getting to places that are hard (or impossible) for 6-axis robots to reach, like the underside of car bodies.

The key perk with the BU is that, rather than having sealer dispensing from a third-party supplier, this robot is fully Kawasaki: seal pump, material and everything else. So if you have a desire for an all-in-one sealing robot, the BU is perfect. It’s all packed in.

No matter your robotic application, there’s probably a Kawasaki robot for it.

Regardless of industry, task or payload, Kawasaki Robotics is known for building and supporting strong, intuitive and versatile robots. Whenever you’re ready, talk to us about your application.